We have what you need

Products

Throughout our manufacturing processes we utilize a series of checks and balances to ensure quality is built into everything we do.

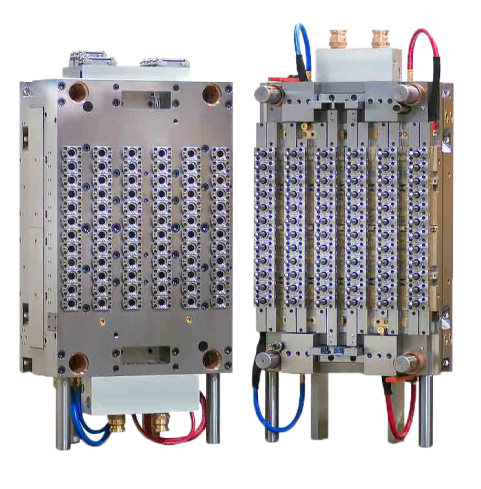

- PET Preform Molds

- Hot Runner Systems

- End-of-Arm take out systems

- Prototype “Modular” Stacks

Services

- Cold half refurbishments with factory qualification

- Cold half conversions with factory qualification

- Hot runner refurbishments

- End-of-Arm Tooling (EOAT) refurbishments

- Alterations / Tooling repair

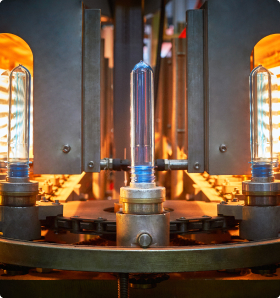

- Modular prototyping tooling and pilot preform production

- Sidel SB01 in-house to provide finished bottles and accelerate your design cycle

Our expertise is your advantage

We strive to meet and exceed our customers expectations, each and every time.

Why should you work with EFI?

The real question is, why wouldn’t you? There are so many benefits we can only list a few here.

Flexible.

Manufacturing for leading machine platforms “True mold builder” allows EFI customers spec tooling to run in multiple machine platforms

Custom.

Paired hot runners and end-of-arm tooling (EOAT) for each design

Reliable.

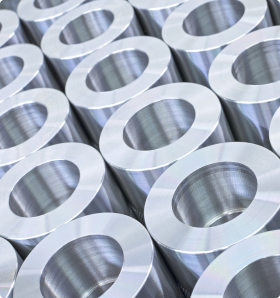

Replacement parts available for EFI or non-EFI systems

Precise.

Shrink library and experienced engineers hit target weights and precision machining delivers precise results as measured by CPK’s

All for one, one for all

We pride ourselves in our professionalism and sense of urgency in providing the best value for you and your customers.